Чекрк — разлика између измена

Спашавам 1 извора и означавам 0 мртвим.) #IABot (v2.0.8.6 |

. ознака: везе до вишезначних одредница |

||

| Ред 37: | Ред 37: | ||

|isbn=978-0-13-516062-6 |

|isbn=978-0-13-516062-6 |

||

}}</ref> Ова справа се користи од давнина, посебно у [[ратна морнарица|морнарици]]. У зависности од намене, постоје различите изведбе чекрка (са променљивим бројем и распоредом точкова) и могу бити израђени од различитих материјала ([[Дрво (материјал)|дрвета]], [[метал]]а, [[пластика|пластике]] и др). |

}}</ref> Ова справа се користи од давнина, посебно у [[ратна морнарица|морнарици]]. У зависности од намене, постоје различите изведбе чекрка (са променљивим бројем и распоредом точкова) и могу бити израђени од различитих материјала ([[Дрво (материјал)|дрвета]], [[метал]]а, [[пластика|пластике]] и др). |

||

== Блок и прибор == |

|||

{{рут}} |

|||

[[Датотека:Tackles.png|thumb|360px|right|Various ways of rigging a tackle<ref name="advantage" />]] |

|||

A block is a set of pulleys (wheels) assembled so that each pulley rotates independently from every other pulley. Two blocks with a rope attached to one of the blocks and threaded through the two sets of pulleys form a [[block and tackle]].<ref>{{cite web |

|||

|last = Prater |first = Edward L. |

|||

|title = Basic Machines |

|||

|publisher = Naval Education and Training Professional Development and Technology Center, NAVEDTRA 14037 |date = 1994 |

|||

|url = http://www.constructionknowledge.net/public_domain_documents/Div_1_General/Basic_Skills/Basic%20Machines%20NAVEDTRA%2014037%201994.pdf |

|||

}}</ref> |

|||

<ref>{{cite book |

|||

|author = Bureau of Naval Personnel |

|||

|title = Basic Machines and How They Work |

|||

|publisher = Dover Publications |

|||

|date = 1971 |

|||

|orig-year = 1965 |

|||

|url = http://www.webpal.org/SAFE/aaarecovery/5_simple_technology/basic_machines.pdf |

|||

|isbn = 0-486-21709-4 |

|||

|access-date = 2011-12-13 |

|||

|archive-url = https://web.archive.org/web/20160922221747/http://www.webpal.org/SAFE/aaarecovery/5_simple_technology/basic_machines.pdf |

|||

|archive-date = 2016-09-22 |

|||

|url-status = dead |

|||

}}</ref> |

|||

A [[block and tackle]] is assembled so one block is attached to fixed mounting point and the other is attached to the moving load. The [[ideal mechanical advantage]] of the block and tackle is equal to the number of sections of the rope that support the moving block. |

|||

In the diagram on the right the ideal mechanical advantage of each of the block and tackle assemblies<ref name="advantage">{{cite book |title=Handbook of Rigging: For Construction and Industrial Operations |url=https://books.google.com/books?id=Q86UKqYui-0C |publisher=McGraw-Hill Professional |isbn=978-0-07-149301-7 |last=MacDonald |first=Joseph A |date = 14 June 2008|pages=376}}</ref> shown is as follows: |

|||

* Gun tackle: 2 |

|||

* Luff tackle: 3 |

|||

* Double tackle: 4 |

|||

* Gyn tackle: 5 |

|||

* Threefold purchase: 6 |

|||

== Системи ужади и ременица == |

|||

[[Датотека:Pulley in Oil Well.jpg|thumb|upright|Pulley in oil derrick]] |

|||

[[Датотека:Crane pulley 4x.jpg|thumb|upright|A hoist using the compound pulley system yielding an advantage of 4. The single fixed pulley is installed on the [[hoist (device)|hoist]]. The two movable pulleys (joined) are attached to the [[Lifting hook|hook]]. One end of the rope is attached to the crane frame, another to the winch.]] |

|||

A rope and pulley system—that is, a [[block and tackle]]—is characterised by the use of a single continuous rope to transmit a tension force around one or more pulleys to lift or move a load—the rope may be a light line or a strong cable. This system is included in the list of [[simple machine]]s identified by Renaissance scientists.<ref>{{cite book |

|||

| last = Avery |

|||

| first = Elroy |

|||

| title = Elementary physics |

|||

| year = 1878 |

|||

| publisher = Sheldon and company |

|||

| url = https://archive.org/details/elementaryphysi01avergoog |

|||

| page = [https://archive.org/details/elementaryphysi01avergoog/page/n471 459] |

|||

| quote = wheel and axle. |

|||

}}</ref><ref name="Bowser">{{cite book |

|||

| last = Bowser |

|||

| first = Edward |

|||

| title = An elementary treatise on analytic mechanics: With numerous examples |

|||

| publisher = D. Van Nostrand company |

|||

| url=https://books.google.com/books?id=UdM3AAAAMAAJ&q=simple+machine&pg=PR9 |

|||

| edition = 5 |

|||

| date = 1890 |

|||

| pages = 180}}</ref> |

|||

If the rope and pulley system does not dissipate or store energy, then its [[mechanical advantage]] is the number of parts of the rope that act on the load. This can be shown as follows. |

|||

Consider the set of pulleys that form the moving block and the parts of the rope that support this block. If there are ''p'' of these parts of the rope supporting the load ''W,'' then a force balance on the moving block shows that the tension in each of the parts of the rope must be ''W/p.'' This means the input force on the rope is ''T''=''W/p.'' Thus, the block and tackle reduces the input force by the factor ''p.'' |

|||

<gallery> |

|||

Image:Polispasto2B.jpg|A gun tackle has a single pulley in both the fixed and moving blocks with two rope parts supporting the load ''W.'' |

|||

Image:Pulley1a.svg|Separation of the pulleys in the gun tackle show the force balance that results in a rope tension of ''W/2.'' |

|||

</gallery> |

|||

<gallery> |

|||

Image:Polispasto4.jpg|A double tackle has two pulleys in both the fixed and moving blocks with four rope parts supporting the load ''W.'' |

|||

Image:Pulley3a.svg|Separation of the pulleys in the double tackle show the force balance that results in a rope tension of ''W/4.'' |

|||

</gallery> |

|||

=== Начин рада === |

|||

The simplest theory of operation for a pulley system assumes that the pulleys and lines are weightless. And that there is no energy loss due to friction. It is also assumed that the lines do not stretch. |

|||

In equilibrium, the forces on the moving block must sum to zero. In addition the tension in the rope must be the same for each of its parts. This means that the two parts of the rope supporting the moving block must each support half the load. |

|||

<gallery> |

|||

Image:Polea-simple-fija.jpg|Fixed pulley |

|||

Image:Pulley0.svg|Diagram 1: The load ''F'' on the moving pulley is balanced by the tension in two parts of the rope supporting the pulley. |

|||

Image:Polea-simple-movil2.jpg|Movable pulley |

|||

Image:Pulley1.svg|Diagram 2: A movable pulley lifting the load ''W'' is supported by two rope parts with tension ''W/2.'' |

|||

</gallery> |

|||

These are different types of pulley systems: |

|||

* '''Fixed:''' A ''fixed'' pulley has an axle mounted in bearings attached to a supporting structure. A fixed pulley changes the direction of the force on a rope or belt that moves along its circumference. Mechanical advantage is gained by combining a fixed pulley with a movable pulley or another fixed pulley of a different diameter. |

|||

* '''Movable:''' A ''movable'' pulley has an axle in a movable block. A single movable pulley is supported by two parts of the same rope and has a mechanical advantage of two. |

|||

* '''Compound:''' A combination of fixed and movable pulleys forms a [[block and tackle]]. A ''block and tackle'' can have several pulleys mounted on the fixed and moving axles, further increasing the mechanical advantage. |

|||

<gallery> |

|||

Image:Pulley2.svg|Diagram 3: The gun tackle "rove to advantage" has the rope attached to the moving pulley. The tension in the rope is ''W/3'' yielding an advantage of three. |

|||

Image:Pulley2a.svg|Diagram 3a: The Luff tackle adds a fixed pulley "rove to disadvantage." The tension in the rope remains ''W/3'' yielding an advantage of three. |

|||

</gallery> |

|||

The mechanical advantage of the gun tackle can be increased by interchanging the fixed and moving blocks so the rope is attached to the moving block and the rope is pulled in the direction of the lifted load. In this case the [[block and tackle]] is said to be "rove to advantage."<ref>{{cite web |

|||

| title = Seamanship Reference, Chapter 5, General Rigging |

|||

| publisher = sccheadquarters.com |

|||

| url = http://www.sccheadquarters.com/Data/Sites/1/media/Training/TrainingInstructions/seamanship/Chapter%205%20-%20General%20Rigging.pdf |

|||

}}</ref> Diagram 3 shows that now three rope parts support the load ''W'' which means the tension in the rope is ''W/3''. Thus, the mechanical advantage is three. |

|||

===Free body diagrams=== |

|||

The [[mechanical advantage]] of a pulley system can be analysed using [[free body diagram]]s which balance the [[tension (physics)|tension force]] in the rope with the [[force of gravity]] on the load. In an ideal system, the massless and frictionless pulleys do not dissipate energy and allow for a change of direction of a rope that does not stretch or wear. In this case, a force balance on a free body that includes the load, ''W'', and ''n'' supporting sections of a rope with tension ''T'', yields: |

|||

:<math>n T -W = 0.</math> |

|||

The ratio of the load to the input tension force is the mechanical advantage ''MA'' of the pulley system,<ref name="Tiner">Tiner, J. H. ''Exploring the World of Physics: From Simple Machines to Nuclear Energy''. Master Books (May 1, 2006) p. 68.</ref> |

|||

:<math>MA = \frac{W}{T} = n.</math> |

|||

Thus, the mechanical advantage of the system is equal to the number of sections of rope supporting the load. |

|||

== Системи ремена и ременица == |

|||

[[Датотека:Flachriemen.png|thumb|left|Flat belt on a belt pulley]] |

|||

[[Датотека:Keilriemen-V-Belt.png|thumb|Belt and pulley system]] |

|||

[[Датотека:PutnamLatheHagley01.jpg|thumb|Cone pulley driven from above by a [[line shaft]]]] |

|||

A belt and pulley system is characterized by two or more pulleys in common to a [[belt (mechanical)|belt]]. This allows for [[power (physics)|mechanical power]], [[torque]], and [[speed]] to be transmitted across axles. If the pulleys are of differing diameters, a mechanical advantage is realized. |

|||

In the case of a drum-style pulley, without a groove or flanges, the pulley often is slightly convex to keep the [[belt (mechanical)#Flat belts|flat belt]] centered. It is sometimes referred to as a crowned pulley. Though once widely used on factory [[line shaft]]s, this type of pulley is still found driving the rotating brush in upright [[vacuum cleaner]]s, in [[belt sander]]s and [[bandsaw]]s.<ref>{{cite web|url=http://woodgears.ca/bandsaw/crowned_pulleys.html|title=How crowned pulleys keep a flat belt tracking|publisher=Wood Gears}}</ref> Agricultural [[tractors]] built up to the early 1950s generally had a belt pulley for a flat belt (which is what ''[[Belt Pulley]]'' magazine was named after). It has been replaced by other mechanisms with more flexibility in methods of use, such as [[power take-off]] and [[hydraulic machinery|hydraulics]]. |

|||

With belts and pulleys, friction is one of the most important forces. Some uses for belts and pulleys involve peculiar angles (leading to bad belt tracking and possibly slipping the belt off the pulley) or low belt-tension environments, causing unnecessary slippage of the belt and hence extra wear to the belt. To solve this, pulleys are sometimes lagged. Lagging is the term used to describe the application of a coating, cover or wearing surface with various textured patterns which is sometimes applied to pulley shells. Lagging is often applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction between the belt and the pulley. Notably drive pulleys are often rubber lagged (coated with a rubber friction layer) for exactly this reason.<ref>{{cite web |title=Pulley Lagging |publisher=CKIT |url=https://www.ckit.co.za/secure/conveyor/troughed/pulleys/pulley_lagging.htm |access-date=17 June 2022}}</ref> |

|||

== Референце == |

== Референце == |

||

| Ред 42: | Ред 157: | ||

== Литература == |

== Литература == |

||

{{refbegin|30em}} |

|||

* {{Cite book|ref= harv| last = Paul |

* {{Cite book|ref= harv| last = Paul |

||

| first = Burton |

| first = Burton |

||

| Ред 74: | Ред 190: | ||

| doi = |

| doi = |

||

|isbn=978-0-486-25593-4}} |

|isbn=978-0-486-25593-4}} |

||

* {{Citation |last1=Paul |first1=Akshoy |last2=Roy |first2=Pijush |last3=Mukherjee |first3=Sanchayan |title=Mechanical sciences: engineering mechanics and strength of materials |year=2005 |publisher=Prentice Hall of India |isbn=978-81-203-2611-8 |page=215 |postscript=.}} |

|||

* {{Citation |last=Asimov |first=Isaac |title=Understanding Physics |year=1988 |publisher=Barnes & Noble |location=New York |isbn=978-0-88029-251-1 |url=https://books.google.com/books?id=pSKvaLV6zkcC&q=Asimov+simple+machine&pg=PA88 |page=88 |postscript=.}} |

|||

* {{cite book |

|||

|last=Anderson |

|||

|first=William Ballantyne |

|||

|title=Physics for Technical Students: Mechanics and Heat |

|||

|year=1914 |

|||

|publisher=McGraw Hill |

|||

|location=New York |

|||

|url=https://archive.org/details/bub_gb_Pa0IAAAAIAAJ/page/n131 |

|||

|access-date=2008-05-11 |

|||

|pages=112}} |

|||

* {{cite encyclopedia |

|||

| title = Mechanics |

|||

| encyclopedia = Encyclopædia Britannica |

|||

| volume = 3 |

|||

| pages = 44 |

|||

| publisher = John Donaldson |

|||

| date =1773 |

|||

| url = https://books.google.com/books?id=Ow8UAAAAQAAJ&q=%22simple+machine%22+%22mechanical+powers%22+lever+screw+inclined+plane+wedge+wheel+pulley&pg=PA44 |

|||

| access-date = 5 April 2020}} |

|||

* {{cite book |

|||

| last1 = Morris |

|||

| first1 = Christopher G. |

|||

| title = Academic Press Dictionary of Science and Technology |

|||

| publisher = Gulf Professional Publishing |

|||

| date = 1992 |

|||

| pages = 1993 |

|||

| url = https://books.google.com/books?id=nauWlPTBcjIC&q=%22simple+machine%22&pg=PA1993 |

|||

| isbn = 9780122004001 |

|||

}} |

|||

* {{Citation|url=http://galileo.phys.virginia.edu/outreach/8thgradesol/compoundmachine.htm | title=Compound machines|publisher=University of Virginia Physics Department|access-date=2010-06-11|postscript=.}}</ref><ref name="Usher">{{cite book|last=Usher|first=Abbott Payson |title=A History of Mechanical Inventions|publisher=Courier Dover Publications|year=1988|location=US|pages=98 | url=https://books.google.com/books?id=xuDDqqa8FlwC&q=wedge+and+screw&pg=PA196 |isbn=978-0-486-25593-4}} |

|||

* {{cite conference |last=Wallenstein |first=Andrew |title=Foundations of cognitive support: Toward abstract patterns of usefulness |date=June 2002 |book-title=Proceedings of the 9th Annual Workshop on the Design, Specification, and Verification of Interactive Systems |publisher=Springer |url=https://books.google.com/books?id=G9sZf7D24a8C&q=simple+machines&pg=PA136 |access-date=2008-05-21 |page=136|isbn=9783540002666 }} |

|||

* {{Citation|last=Prater|first=Edward L.|year=1994|title=Basic machines | url=http://www.constructionknowledge.net/public_domain_documents/Div_1_General/Basic_Skills/Basic%20Machines%20NAVEDTRA%2014037%201994.pdf |publisher=U.S. Navy Naval Education and Training Professional Development and Technology Center, NAVEDTRA 14037|postscript=.}} |

|||

* {{Citation|author=U.S. Navy Bureau of Naval Personnel|year=1971| url=http://www.webpal.org/SAFE/aaarecovery/5_simple_technology/basic_machines.pdf | title=Basic machines and how they work|publisher=Dover Publications|postscript=.}} |

|||

* {{Citation |last=Reuleaux |first=F. |orig-year=1876 |year=1963 |title=The kinematics of machinery (translated and annotated by A.B.W. Kennedy) |publisher=reprinted by Dover |location=New York |postscript=.}} |

|||

* {{Citation |author=Cornell University |author-link=Cornell University |title=Reuleaux Collection of Mechanisms and Machines at Cornell University |url=http://kmoddl.library.cornell.edu/rx_collection.php |publisher=Cornell University |postscript=.}} |

|||

{{refend}} |

|||

== Спољашње везе == |

== Спољашње везе == |

||

{{Commons category|Pulleys}} |

|||

{{Други пројекти |

|||

| commons = Pulleys |

|||

| wikispecies = |

|||

| wiktionary = Чекрк |

|||

| wikiversity = |

|||

| wikibooks = |

|||

| wikisource = |

|||

| wikiquote = |

|||

| wikinews = |

|||

}} |

|||

* [http://www.khanacademy.org/science/physics/mechanics/v/mechanical-advantage--part-3 -{Mechanical advantage}-] {{Wayback|url=http://www.khanacademy.org/science/physics/mechanics/v/mechanical-advantage--part-3 |date=20121113001603 }} |

* [http://www.khanacademy.org/science/physics/mechanics/v/mechanical-advantage--part-3 -{Mechanical advantage}-] {{Wayback|url=http://www.khanacademy.org/science/physics/mechanics/v/mechanical-advantage--part-3 |date=20121113001603 }} |

||

Верзија на датум 24. децембар 2022. у 01:21

Чекрк је механичка справа која служи за скретање смера силе или за подизање или повлачење великих терета коришћењем мале силе.[1] Састоји се од једног или више точкова који могу да се окрећу око својих осовина. Обод точка може да буде раван, назупчен или удубљен и преко њега се превлачи конопац, ремен, ланац и сл.[2][3] Ова справа се користи од давнина, посебно у морнарици. У зависности од намене, постоје различите изведбе чекрка (са променљивим бројем и распоредом точкова) и могу бити израђени од различитих материјала (дрвета, метала, пластике и др).

Блок и прибор

Један корисник управо ради на овом чланку. Молимо остале кориснике да му допусте да заврши са радом. Ако имате коментаре и питања у вези са чланком, користите страницу за разговор.

Хвала на стрпљењу. Када радови буду завршени, овај шаблон ће бити уклоњен. Напомене

|

A block is a set of pulleys (wheels) assembled so that each pulley rotates independently from every other pulley. Two blocks with a rope attached to one of the blocks and threaded through the two sets of pulleys form a block and tackle.[5] [6]

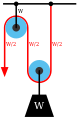

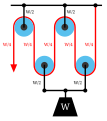

A block and tackle is assembled so one block is attached to fixed mounting point and the other is attached to the moving load. The ideal mechanical advantage of the block and tackle is equal to the number of sections of the rope that support the moving block.

In the diagram on the right the ideal mechanical advantage of each of the block and tackle assemblies[4] shown is as follows:

- Gun tackle: 2

- Luff tackle: 3

- Double tackle: 4

- Gyn tackle: 5

- Threefold purchase: 6

Системи ужади и ременица

A rope and pulley system—that is, a block and tackle—is characterised by the use of a single continuous rope to transmit a tension force around one or more pulleys to lift or move a load—the rope may be a light line or a strong cable. This system is included in the list of simple machines identified by Renaissance scientists.[7][8]

If the rope and pulley system does not dissipate or store energy, then its mechanical advantage is the number of parts of the rope that act on the load. This can be shown as follows.

Consider the set of pulleys that form the moving block and the parts of the rope that support this block. If there are p of these parts of the rope supporting the load W, then a force balance on the moving block shows that the tension in each of the parts of the rope must be W/p. This means the input force on the rope is T=W/p. Thus, the block and tackle reduces the input force by the factor p.

-

A gun tackle has a single pulley in both the fixed and moving blocks with two rope parts supporting the load W.

-

Separation of the pulleys in the gun tackle show the force balance that results in a rope tension of W/2.

-

A double tackle has two pulleys in both the fixed and moving blocks with four rope parts supporting the load W.

-

Separation of the pulleys in the double tackle show the force balance that results in a rope tension of W/4.

Начин рада

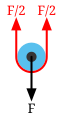

The simplest theory of operation for a pulley system assumes that the pulleys and lines are weightless. And that there is no energy loss due to friction. It is also assumed that the lines do not stretch.

In equilibrium, the forces on the moving block must sum to zero. In addition the tension in the rope must be the same for each of its parts. This means that the two parts of the rope supporting the moving block must each support half the load.

-

Fixed pulley

-

Diagram 1: The load F on the moving pulley is balanced by the tension in two parts of the rope supporting the pulley.

-

Movable pulley

-

Diagram 2: A movable pulley lifting the load W is supported by two rope parts with tension W/2.

These are different types of pulley systems:

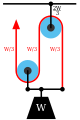

- Fixed: A fixed pulley has an axle mounted in bearings attached to a supporting structure. A fixed pulley changes the direction of the force on a rope or belt that moves along its circumference. Mechanical advantage is gained by combining a fixed pulley with a movable pulley or another fixed pulley of a different diameter.

- Movable: A movable pulley has an axle in a movable block. A single movable pulley is supported by two parts of the same rope and has a mechanical advantage of two.

- Compound: A combination of fixed and movable pulleys forms a block and tackle. A block and tackle can have several pulleys mounted on the fixed and moving axles, further increasing the mechanical advantage.

-

Diagram 3: The gun tackle "rove to advantage" has the rope attached to the moving pulley. The tension in the rope is W/3 yielding an advantage of three.

-

Diagram 3a: The Luff tackle adds a fixed pulley "rove to disadvantage." The tension in the rope remains W/3 yielding an advantage of three.

The mechanical advantage of the gun tackle can be increased by interchanging the fixed and moving blocks so the rope is attached to the moving block and the rope is pulled in the direction of the lifted load. In this case the block and tackle is said to be "rove to advantage."[9] Diagram 3 shows that now three rope parts support the load W which means the tension in the rope is W/3. Thus, the mechanical advantage is three.

Free body diagrams

The mechanical advantage of a pulley system can be analysed using free body diagrams which balance the tension force in the rope with the force of gravity on the load. In an ideal system, the massless and frictionless pulleys do not dissipate energy and allow for a change of direction of a rope that does not stretch or wear. In this case, a force balance on a free body that includes the load, W, and n supporting sections of a rope with tension T, yields:

The ratio of the load to the input tension force is the mechanical advantage MA of the pulley system,[10]

Thus, the mechanical advantage of the system is equal to the number of sections of rope supporting the load.

Системи ремена и ременица

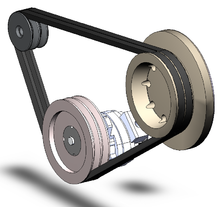

A belt and pulley system is characterized by two or more pulleys in common to a belt. This allows for mechanical power, torque, and speed to be transmitted across axles. If the pulleys are of differing diameters, a mechanical advantage is realized.

In the case of a drum-style pulley, without a groove or flanges, the pulley often is slightly convex to keep the flat belt centered. It is sometimes referred to as a crowned pulley. Though once widely used on factory line shafts, this type of pulley is still found driving the rotating brush in upright vacuum cleaners, in belt sanders and bandsaws.[11] Agricultural tractors built up to the early 1950s generally had a belt pulley for a flat belt (which is what Belt Pulley magazine was named after). It has been replaced by other mechanisms with more flexibility in methods of use, such as power take-off and hydraulics.

With belts and pulleys, friction is one of the most important forces. Some uses for belts and pulleys involve peculiar angles (leading to bad belt tracking and possibly slipping the belt off the pulley) or low belt-tension environments, causing unnecessary slippage of the belt and hence extra wear to the belt. To solve this, pulleys are sometimes lagged. Lagging is the term used to describe the application of a coating, cover or wearing surface with various textured patterns which is sometimes applied to pulley shells. Lagging is often applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction between the belt and the pulley. Notably drive pulleys are often rubber lagged (coated with a rubber friction layer) for exactly this reason.[12]

Референце

- ^ Usher, Abbott Payson (1988). A History of Mechanical Inventions. USA: Courier Dover Publications. ISBN 978-0-486-25593-4.

- ^ Uicker, John; Pennock, Gordon; Shigley, Joseph (2010). Theory of Machines and Mechanisms (4th изд.). Oxford University Press, USA. ISBN 978-0-19-537123-9.

- ^ Paul, Burton (1979). Kinematics and dynamics of planar machinery (illustrated изд.). Prentice-Hall. ISBN 978-0-13-516062-6.

- ^ а б MacDonald, Joseph A (14. 6. 2008). Handbook of Rigging: For Construction and Industrial Operations. McGraw-Hill Professional. стр. 376. ISBN 978-0-07-149301-7.

- ^ Prater, Edward L. (1994). „Basic Machines” (PDF). Naval Education and Training Professional Development and Technology Center, NAVEDTRA 14037.

- ^ Bureau of Naval Personnel (1971) [1965]. Basic Machines and How They Work (PDF). Dover Publications. ISBN 0-486-21709-4. Архивирано из оригинала (PDF) 2016-09-22. г. Приступљено 2011-12-13.

- ^ Avery, Elroy (1878). Elementary physics. Sheldon and company. стр. 459. „wheel and axle.”

- ^ Bowser, Edward (1890). An elementary treatise on analytic mechanics: With numerous examples (5 изд.). D. Van Nostrand company. стр. 180.

- ^ „Seamanship Reference, Chapter 5, General Rigging” (PDF). sccheadquarters.com.

- ^ Tiner, J. H. Exploring the World of Physics: From Simple Machines to Nuclear Energy. Master Books (May 1, 2006) p. 68.

- ^ „How crowned pulleys keep a flat belt tracking”. Wood Gears.

- ^ „Pulley Lagging”. CKIT. Приступљено 17. 6. 2022.

Литература

- Paul, Burton (1979). Kinematics and dynamics of planar machinery (illustrated изд.). Prentice-Hall. ISBN 978-0-13-516062-6.

- Uicker, John; Pennock, Gordon; Shigley, Joseph (2010). Theory of Machines and Mechanisms (4th изд.). Oxford University Press, USA. ISBN 978-0-19-537123-9.

- Usher, Abbott Payson (1988). A History of Mechanical Inventions. USA: Courier Dover Publications. стр. 98. ISBN 978-0-486-25593-4.

- Paul, Akshoy; Roy, Pijush; Mukherjee, Sanchayan (2005), Mechanical sciences: engineering mechanics and strength of materials, Prentice Hall of India, стр. 215, ISBN 978-81-203-2611-8.

- Asimov, Isaac (1988), Understanding Physics, New York: Barnes & Noble, стр. 88, ISBN 978-0-88029-251-1.

- Anderson, William Ballantyne (1914). Physics for Technical Students: Mechanics and Heat. New York: McGraw Hill. стр. 112. Приступљено 2008-05-11.

- „Mechanics”. Encyclopædia Britannica. 3. John Donaldson. 1773. стр. 44. Приступљено 5. 4. 2020.

- Morris, Christopher G. (1992). Academic Press Dictionary of Science and Technology. Gulf Professional Publishing. стр. 1993. ISBN 9780122004001.

- Compound machines, University of Virginia Physics Department, Приступљено 2010-06-11.</ref><ref name="Usher">Usher, Abbott Payson (1988). A History of Mechanical Inventions. US: Courier Dover Publications. стр. 98. ISBN 978-0-486-25593-4.

- Wallenstein, Andrew (јун 2002). „Foundations of cognitive support: Toward abstract patterns of usefulness”. Proceedings of the 9th Annual Workshop on the Design, Specification, and Verification of Interactive Systems. Springer. стр. 136. ISBN 9783540002666. Приступљено 2008-05-21.

- Prater, Edward L. (1994), Basic machines (PDF), U.S. Navy Naval Education and Training Professional Development and Technology Center, NAVEDTRA 14037.

- U.S. Navy Bureau of Naval Personnel (1971), Basic machines and how they work (PDF), Dover Publications.

- Reuleaux, F. (1963) [1876], The kinematics of machinery (translated and annotated by A.B.W. Kennedy), New York: reprinted by Dover.

- Cornell University, Reuleaux Collection of Mechanisms and Machines at Cornell University, Cornell University.

Спољашње везе

- Mechanical advantage Архивирано на сајту Wayback Machine (13. новембар 2012)