Папир — разлика између измена

м Разне исправке; козметичке измене |

. |

||

| Ред 1: | Ред 1: | ||

[[Датотека:ManilaPaper.jpg|250п|мини|Манилски папир]] |

[[Датотека:ManilaPaper.jpg|250п|мини|Манилски папир]] |

||

[[Датотека:Papier - various papers in day.jpg|250п|thumb|Различити типови папира: [[картон]], [[папирна марамица]]]] |

[[Датотека:Papier - various papers in day.jpg|250п|thumb|Различити типови папира: [[картон]], [[папирна марамица]]]] |

||

{{рут}} |

|||

'''Папир''' или '''хартија''' је танак слој [[Целулоза|целулоидних]] влакана најчешће [[Правоугаоник|правоугаоног]] облика који у већини случајева служи за [[штампарство|штампање]], [[писање]] или [[цртеж|цртање]] по њему. Прави се разних облика и [[Формати папира|формата]], као и разних [[боја]]. |

'''Папир''' или '''хартија''' је танак слој [[Целулоза|целулоидних]] влакана најчешће [[Правоугаоник|правоугаоног]] облика који у већини случајева служи за [[штампарство|штампање]], [[писање]] или [[цртеж|цртање]] по њему. Прави се разних облика и [[Формати папира|формата]], као и разних [[боја]]. |

||

| Ред 15: | Ред 15: | ||

Потом се ово сазнање проширило и на [[Европа|Европу]] и радионице за израду папира појавиле су се свуда где је било довољно воде за производњу папира.<ref name="Burns 1996, 417f.">{{harvnb|Burns|1996|pp=417f.}}</ref> Око [[800]]. у Багдаду се прави прва фабрика папира.<ref>Murray, Stuart A. P. ''The Library: An illustrated History''. Skyhorse Publishing, (2009). стр. 57.</ref> Производња се ширила преко [[Сирија|Сирије]] и [[Египат|Египта]] на [[Сицилија|Сицилију]] и у [[Андалузија|Андалузију]]. Тако се у 13. веку папир проширио Европом и заменио скупоцјени и ретки [[папирус]] и [[пергамент]]. |

Потом се ово сазнање проширило и на [[Европа|Европу]] и радионице за израду папира појавиле су се свуда где је било довољно воде за производњу папира.<ref name="Burns 1996, 417f.">{{harvnb|Burns|1996|pp=417f.}}</ref> Око [[800]]. у Багдаду се прави прва фабрика папира.<ref>Murray, Stuart A. P. ''The Library: An illustrated History''. Skyhorse Publishing, (2009). стр. 57.</ref> Производња се ширила преко [[Сирија|Сирије]] и [[Египат|Египта]] на [[Сицилија|Сицилију]] и у [[Андалузија|Андалузију]]. Тако се у 13. веку папир проширио Европом и заменио скупоцјени и ретки [[папирус]] и [[пергамент]]. |

||

У 19. веку је индустирјализација знатно редуковала трошак производње папира. Године 1844. је канадски инвеститор [[Charles Fenerty|Чарлс Фенерти]] и Немац Ф. Г. Келер независно развили процесе за |

У 19. веку је индустирјализација знатно редуковала трошак производње папира. Године 1844. је канадски инвеститор [[Charles Fenerty|Чарлс Фенерти]] и Немац Ф. Г. Келер независно развили процесе за пулповање дрвених влакана.<ref>{{Cite book|url=http://www.charlesfenerty.ca/book.html|title=Charles Fenerty and his paper invention |last=Burger|first=Peter |date=2007|publisher=Peter Burger|location=Toronto|isbn=9780978331818|oclc=173248586|pages=25–30}}</ref> |

||

== Рани извори влакана == |

== Рани извори влакана == |

||

[[Датотека:ANCIENT_SANSKRIT_ON_HEMP_BASED_PAPER._HEMP_WAS_A_COMMON_AND_DURABLE_FIBRE_IN_THE_PRODUCTION_OF_%22RAG%22_PAPER_FROM_200_BCE_TO_THE_1850_AD.jpg|left|thumb |Антички Санскрит на папиру базираном на конпљи. Влакна конопље су широко кориштена за придукцију папира од 200. п. н. е. до касних 1800-тих.]] |

[[Датотека:ANCIENT_SANSKRIT_ON_HEMP_BASED_PAPER._HEMP_WAS_A_COMMON_AND_DURABLE_FIBRE_IN_THE_PRODUCTION_OF_%22RAG%22_PAPER_FROM_200_BCE_TO_THE_1850_AD.jpg|left|250px|thumb |Антички Санскрит на папиру базираном на конпљи. Влакна конопље су широко кориштена за придукцију папира од 200. п. н. е. до касних 1800-тих.]] |

||

{{see also|дрвена пулпа|деинковање}} |

{{see also|дрвена пулпа|деинковање}} |

||

| Ред 30: | Ред 30: | ||

== Производња папира == |

== Производња папира == |

||

[[Датотека:Making Paper.gif|мини|right|250п|Прављење папира на кинески начин]] |

[[Датотека:Making Paper.gif|мини|right|250п|Прављење папира на кинески начин]] |

||

Као сировину, Кинези су користили кору [[дуд]]а или [[бамбус]], [[Европа|Европљани]] су користили старе крпе од [[памук]]а и [[лан]]а, док се данас дрвета тачније од [[Целулоза|целулозе]]. Папир је изразито значајно допринео просвети и науци. Проналазак папира сматра се једним од показатеља почетка новог века. Користи се у разне сврхе и може се наћи у разним облицима. |

Као сировину, Кинези су користили кору [[дуд]]а или [[бамбус]], [[Европа|Европљани]] су користили старе крпе од [[памук]]а и [[лан]]а, док се данас дрвета тачније од [[Целулоза|целулозе]]. Папир је изразито значајно допринео просвети и науци. Проналазак папира сматра се једним од показатеља почетка новог века. Користи се у разне сврхе и може се наћи у разним облицима. |

||

Основно средство за ручну производњу хартије је калуп за захватање натопљене пулпе. Добри калупи са [[исток]]а су лепо израђени и имали су оквир са шаркама за држање [[сито|сита]]. Мајстор наизменично спушта и извлачи калуп из базена и лагано га тресе да би се пулпа раширила по ситу. Стезаљке се затим отворе а сито се извади. Калупи на Западу имају сито од танке жице уместо бамбуса. |

Основно средство за ручну производњу хартије је калуп за захватање натопљене пулпе. Добри калупи са [[исток]]а су лепо израђени и имали су оквир са шаркама за држање [[сито|сита]]. Мајстор наизменично спушта и извлачи калуп из базена и лагано га тресе да би се пулпа раширила по ситу. Стезаљке се затим отворе а сито се извади. Калупи на Западу имају сито од танке жице уместо бамбуса. |

||

[[Датотека:Bambus.JPG|мини|лево| |

[[Датотека:Bambus.JPG|мини|лево|250п|Бамбус — сировина на истоку]] |

||

[[Мајстор]] ставља калуп у базен, пулпа се скупља на калупу а течност се цеди остављајући на ситу беома танак слој влакана. Цеђење се ради када [[влакна]] направе влажан [[лист]] папира. Листови се слажу један преко другог, а [[вода]] се циједи притиском камена или помоћу пресе која личи на штампарску. [[Ислам]]ски мајстори први су направили хартију у боји. Они су на њу наносили чак и [[Злато|златне]] или [[Сребро|сребрне]] зачкице. Данас имамо хартију у свим могућим бојама. Нарочита хартија као она што су је правили [[муслимани]] може се користити за писање диплома или свједочанстава. |

[[Мајстор]] ставља калуп у базен, пулпа се скупља на калупу а течност се цеди остављајући на ситу беома танак слој влакана. Цеђење се ради када [[влакна]] направе влажан [[лист]] папира. Листови се слажу један преко другог, а [[вода]] се циједи притиском камена или помоћу пресе која личи на штампарску. [[Ислам]]ски мајстори први су направили хартију у боји. Они су на њу наносили чак и [[Злато|златне]] или [[Сребро|сребрне]] зачкице. Данас имамо хартију у свим могућим бојама. Нарочита хартија као она што су је правили [[муслимани]] може се користити за писање диплома или свједочанстава. |

||

=== Хемијско пулповање === |

|||

{{Main|kraft process|sulfite process|soda pulping}} |

|||

Да би се формирала пулпа од дрвета, a [[chemical pulping process]] separates [[lignin]] from [[cellulose]] fibres. This is accomplished by dissolving [[lignin]] in a cooking liquor, so that it may be washed from the [[cellulose]]; this preserves the length of the cellulose fibres. Paper made from chemical pulps are also known as [[wood-free paper]]s–not to be confused with [[tree-free paper]]; this is because they do not contain lignin, which deteriorates over time. The pulp can also be [[bleaching of wood pulp|bleached]] to produce white paper, but this consumes 5% of the fibres; chemical pulping processes are not used to make paper made from cotton, which is already 90% cellulose. |

|||

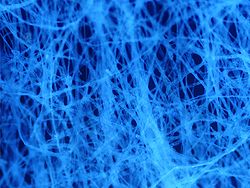

[[Датотека:PaperAutofluorescence.jpg|thumb|250px|right|Микроскопска структура папира: [[Микрографија]] папира који [[autofluorescence|аутофлуоресцира]] под [[Ултраљубичасто зрачење|ултраљубичастом]] илуминацијом. Индивидуална влакна у овом узорку имају око 10 [[микрометар|-{µm}-]] у пречнику.]] |

|||

There are three main chemical pulping processes: the [[sulfite process]] dates back to the 1840s and it was the dominant method extent before the second world war. The [[kraft process]], invented in the 1870s and first used in the 1890s, is now the most commonly practiced strategy, one of its advantages is the chemical reaction with lignin, that produces heat, which can be used to run a generator. Most pulping operations using the kraft process are net contributors to the electricity grid or use the electricity to run an adjacent paper mill. Another advantage is that this process recovers and reuses all inorganic chemical reagents. [[Soda pulping]] is another specialty process used to pulp [[straw]]s, [[bagasse]] and [[hardwoods]] with high [[silicate]] content. |

|||

=== Механичко пулповање === |

|||

There are two major mechanical pulps: thermomechanical pulp (TMP) and groundwood pulp (GW). In the TMP process, wood is chipped and then fed into steam heated refiners, where the chips are squeezed and converted to fibres between two steel discs. In the groundwood process, debarked logs are fed into grinders where they are pressed against rotating stones to be made into fibres. Mechanical pulping does not remove the [[lignin]], so the yield is very high, >95%, however it causes the paper thus produced to turn yellow and become brittle over time. Mechanical pulps have rather short fibres, thus producing weak paper. Although large amounts of [[electrical energy]] are required to produce mechanical pulp, it costs less than the chemical kind. |

|||

=== Деинкована пулпа === |

|||

[[Paper recycling]] processes can use either chemically or mechanically produced pulp; by mixing it with water and applying mechanical action the [[hydrogen]] bonds in the paper can be broken and fibres separated again. Most recycled paper contains a proportion of virgin fibre for the sake of quality; generally speaking, de-inked pulp is of the same quality or lower than the collected paper it was made from. |

|||

There are three main classifications of recycled fibre:. |

|||

* Mill broke or internal mill waste – This incorporates any substandard or grade-change paper made within the paper mill itself, which then goes back into the manufacturing system to be re-pulped back into paper. Such out-of-specification paper is not sold and is therefore often not classified as genuine reclaimed recycled fibre, however most paper mills have been reusing their own waste fibre for many years, long before recycling became popular. |

|||

* Preconsumer waste – This is offcut and processing waste, such as guillotine trims and envelope blank waste; it is generated outside the paper mill and could potentially go to landfill, and is a genuine recycled fibre source; it includes de-inked preconsumer (recycled material that has been printed but did not reach its intended end use, such as waste from printers and unsold publications).<ref>[http://www.nrdc.org/ Natural Resource Defense Council]</ref> |

|||

* Postconsumer waste – This is fibre from paper that has been used for its intended end use and includes office waste, magazine papers and newsprint. As the vast majority of this material has been printed – either digitally or by more conventional means such as lithography or rotogravure – it will either be recycled as printed paper or go through a de-inking process first. |

|||

Recycled papers can be made from 100% recycled materials or blended with virgin pulp, although they are (generally) not as strong nor as bright as papers made from the latter. |

|||

=== Адитиви === |

|||

Besides the fibres, pulps may contain fillers such as [[chalk]] or [[china clay]],<ref>{{Cite book|url=https://books.google.com/books?id=SHiQAAAAIAAJ&q=pulps+may+contain+fillers+such+as+chalk+or+china+clay&dq=pulps+may+contain+fillers+such+as+chalk+or+china+clay&hl=en&sa=X&ved=0ahUKEwjs0pmchdHUAhUU6WMKHQOUCNgQ6AEIJDAA|title=Appropriate Technology|date=1996|publisher=Intermediate Technology Publications.|language=en}}</ref> which improve its characteristics for printing or writing.<ref>{{Cite book|url=https://books.google.com/books?id=zp0_a909uyIC&pg=PA203&dq=Besides+the+fibres,+paper+pulps+may+contain+fillers+such+as+chalk+or+china+clay,+which+improve+its+characteristics&hl=en&sa=X&ved=0ahUKEwjGpu7pp_rWAhXL31QKHaHlB9wQ6AEIMzAC|title=Applications of Wet-End Paper Chemistry|last=Thorn|first=Ian|last2=Au|first2=Che On|date=2009-07-24|publisher=Springer Science & Business Media|isbn=9781402060380|language=en}}</ref> Additives for [[sizing]] purposes may be mixed with it or applied to the paper web later in the manufacturing process; the purpose of such sizing is to establish the correct level of surface absorbency to suit ink or paint. |

|||

=== Формирање папира === |

|||

{{Main|Paper machine|papermaking}} |

|||

The [[Pulp (paper)|pulp]] is fed to a paper machine where it is formed as a paper web and the water is removed from it by pressing and drying. |

|||

Pressing the sheet removes the water by force; once the water is forced from the sheet, a special kind of felt, which is not to be confused with the traditional one, is used to collect the water; whereas when making paper by hand, a blotter sheet is used instead. |

|||

Drying involves using air or heat to remove water from the paper sheets. In the earliest days of paper making, this was done by hanging the sheets like laundry; in more modern times, various forms of heated drying mechanisms are used. On the paper machine, the most common is the steam-heated can dryer. These can reach temperatures above {{convert|200|F|C}} and are used in long sequences of more than forty cans where the heat produced by these can easily dry the paper to less than six percent moisture. |

|||

=== Дорада === |

|||

The paper may then undergo [[sizing]] to alter its physical properties for use in various applications. |

|||

Paper at this point is ''uncoated''. [[Coated paper]] has a thin layer of material such as [[calcium carbonate]] or [[china clay]] applied to one or both sides in order to create a surface more suitable for high-resolution [[halftone]] screens. (Uncoated papers are rarely suitable for screens above 150 lpi.) Coated or uncoated papers may have their surfaces polished by [[calender]]ing. Coated papers are divided into matte, semi-matte or silk, and gloss. Gloss papers give the highest [[optical density]] in the printed image. |

|||

The paper is then fed onto reels if it is to be used on web printing presses, or cut into sheets for other printing processes or other purposes. The fibres in the paper basically run in the machine direction. Sheets are usually cut "long-grain", i.e. with the grain parallel to the longer dimension of the sheet. [[Continuous stationery|Continuous form paper]] (or continuous stationery) is cut to width with holes punched at the edges, and folded into stacks. |

|||

==== Финоћа папира ==== |

|||

All paper produced by paper machines as the [[Fourdrinier Machine]] are wove paper, i.e. the wire mesh that transports the web leaves a pattern that has the same density along the paper grain and across the grain. Textured finishes, [[watermark]]s and wire patterns imitating hand-made ''laid'' paper can be created by the use of appropriate rollers in the later stages of the machine. |

|||

Wove paper does not exhibit "laidlines", which are small regular lines left behind on paper when it was handmade in a mould made from rows of metal wires or bamboo. Laidlines are very close together. They run perpendicular to the "chainlines", which are further apart. Handmade paper similarly exhibits "deckle edges", or rough and feathery borders.<ref>[http://www.collectionscanada.gc.ca/forgery/ "Document Doubles"] in a virtual museum exhibition at Library and Archives Canada</ref> |

|||

== Примене == |

|||

Paper can be produced with a wide variety of properties, depending on its intended use. |

|||

*'''For representing value:''' [[paper money]], [[bank note]], [[cheque]], [[security]] (see ''[[security paper]]''), [[voucher]] and [[Ticket (admission)|ticket]] |

|||

*'''For [[Data storage device|storing information]]''': [[book]], [[notebook]], [[graph paper]], [[magazine]], [[newspaper]], [[art]], [[zine]], [[letter (message)|letter]] |

|||

*'''For personal use''': [[diary]], note to remind oneself, etc.; for temporary personal use: scratch paper |

|||

*'''For [[communication]]:''' between individuals and/or groups of people. |

|||

*'''For packaging:''' [[corrugated box]], [[paper bag]], [[envelope]], [[Packing & Wrapping Paper]], [[Paper string]], [[Charta emporetica]] and [[wallpaper]] |

|||

*'''For cleaning:''' [[toilet paper]], [[handkerchief]]s, [[paper towel]]s, [[facial tissue]] and [[cat litter]] |

|||

*'''For construction:''' [[papier-mâché]], [[origami]], [[paper plane]]s, [[quilling]], [[paper honeycomb]], used as a core material in [[composite material]]s, [[paper engineering]], [[construction paper]] and [[paper clothing]] |

|||

*'''For other uses:''' [[emery paper]], [[sandpaper]], [[blotting paper]], [[litmus paper]], [[universal indicator]] paper, [[paper chromatography]], [[electrical insulation paper]] (see also ''[[dielectric]]'' and ''[[permittivity]]'') and [[filter paper]] |

|||

It is estimated that paper-based storage solutions captured 0.33% of the total in 1986 and only 0.007% in 2007, even though in absolute terms, the world's capacity to store information on paper increased from 8.7 to 19.4 [[petabyte]]s.<ref name="HilbertLopez2011">[http://www.sciencemag.org/content/332/6025/60 "The World’s Technological Capacity to Store, Communicate, and Compute Information"], especially [http://www.sciencemag.org/content/suppl/2011/02/08/science.1200970.DC1/Hilbert-SOM.pdf Supporting online material], Martin Hilbert and Priscila López (2011), [[Science (journal)|Science]], 332(6025), 60–65; free access to the article through here: martinhilbert.net/WorldInfoCapacity.html</ref> It is estimated that in 1986 paper-based postal letters represented less than 0.05% of the world's telecommunication capacity, with sharply decreasing tendency after the massive introduction of digital technologies.<ref name="HilbertLopez2011"/> |

|||

== Типови, дебљина и тежина == |

|||

{{Main|Величина папира|Грамажа|Густина папира}} |

|||

[[Датотека:Coloured, textured craft card.jpg|thumb|250п|right|Картонска и папирна галантерија за употребу у [[Занатство|занатству]] је доступна у широком варијетету текстура и боја.]] |

|||

The thickness of paper is often measured by caliper, which is typically given in thousandths of an inch in the United States and in micrometers (µm) in the rest of the world.<ref>{{Cite web|url=http://www.casepaper.com/calc_chart_caliper.htm|title=Paper Thickness Chart|website=Case Paper|language=en-US|access-date=2017-05-27}}</ref> Paper may be between {{convert|0.07|and|0.18|mm|in}} thick.<ref>{{Cite web|url=http://hypertextbook.com/facts/2001/JuliaSherlis.shtml|title=Thickness of a Piece of Paper|last=Elert|first=Glenn|website=The Physics Factbook|language=en|access-date=2017-05-27}}</ref> |

|||

Paper is often characterized by weight. In the United States, the weight assigned to a paper is the weight of a ream, 500 sheets, of varying "basic sizes", before the paper is cut into the size it is sold to end customers. For example, a ream of 20 lb, {{convert|8.5|x|11|in|mm|0|abbr=on}} paper weighs 5 pounds, because it has been cut from a larger sheet into four pieces.<ref>{{Cite book|url=https://www.worldcat.org/oclc/851074844|title=The Hammerhill guide to desktop publishing in business|last=McKenzie|first=Bruce G.|date=1989|publisher=Hammerhill|isbn=9780961565114|oclc=851074844|page=144}}</ref> In the United States, printing paper is generally 20 lb, 24 lb, or 32 lb at most. [[Cover stock]] is generally 68 lb, and 110 lb or more is considered [[card stock]]. |

|||

In Europe, and other regions using the [[ISO 216]] paper sizing system, the weight is expressed in grammes per square metre (g/m<sup>2</sup> or usually just g) of the paper. Printing paper is generally between 60 g and 120 g. Anything heavier than 160 g is considered card. The weight of a ream therefore depends on the dimensions of the paper and its thickness. |

|||

Most commercial paper sold in North America is cut to standard paper sizes based on [[United States customary units|customary units]] and is defined by the length and width of a sheet of paper. |

|||

The ISO 216 system used in most other countries is based on the surface area of a sheet of paper, not on a sheet's width and length. It was first adopted in Germany in 1922 and generally spread as nations adopted the metric system. The largest standard size paper is A0 (A zero), measuring one square meter (approx. 1189 × 841 mm). A1 is half the size of a sheet of A0 (i.e., 594 mm × 841 mm), such that two sheets of A1 placed side by side are equal to one sheet of A0. A2 is half the size of a sheet of A1, and so forth. Common sizes used in the office and the home are A4 and A3 (A3 is the size of two A4 sheets). |

|||

The [[density]] of paper ranges from {{convert|250|kg/m3|lb/ft3|0|abbr=on}} for tissue paper to {{convert|1500|kg/m3|lb/ft3|0|abbr=on}} for some speciality paper. Printing paper is about {{convert|800|kg/m3|lb/ft3|0|abbr=on}}.<ref>{{cite web|url=http://www.paperonweb.com/density.htm|title=Density of paper and paperboard|publisher=PaperOnWeb|accessdate=31 October 2007}}</ref> |

|||

Paper may be classified into seven categories:<ref>{{Cite book|url=https://www.worldcat.org/oclc/959020143|title=The Thames and Hudson manual of bookbinding|last=Johnson|first=Arthur|date=1978|publisher=Thames and Hudson|location=London|oclc=959020143|language=en}}</ref> |

|||

*''Printing papers'' of wide variety. |

|||

*''Wrapping papers'' for the protection of goods and merchandise. This includes wax and kraft papers. |

|||

*''Writing paper'' suitable for stationery requirements. This includes ledger, bank, and bond paper. |

|||

*''Blotting papers'' containing little or no size. |

|||

*''Drawing papers'' usually with rough surfaces used by artists and designers, including cartridge paper. |

|||

*''Handmade papers'' including most decorative papers, [[Ingres paper]]s, [[Japanese paper]] and [[tissue paper|tissues]], all characterized by lack of grain direction. |

|||

*''Specialty papers'' including cigarette paper, toilet tissue, and other industrial papers. |

|||

== Извори == |

== Извори == |

||

Верзија на датум 16. јануар 2018. у 03:34

Један корисник управо ради на овом чланку. Молимо остале кориснике да му допусте да заврши са радом. Ако имате коментаре и питања у вези са чланком, користите страницу за разговор.

Хвала на стрпљењу. Када радови буду завршени, овај шаблон ће бити уклоњен. Напомене

|

Папир или хартија је танак слој целулоидних влакана најчешће правоугаоног облика који у већини случајева служи за штампање, писање или цртање по њему. Прави се разних облика и формата, као и разних боја.

Најбољи папир се прави од биљака које садрже много целулозе у својим влакнима или од крпа од природних материјала као што су памук и лан. Кинези су тврдили да им је јефтиније да производе хартију него свилу и да је она погоднија за писање од трака дрвета или бамбуса, нарочито за неке дугачке књиге. На западу је папир заменио пергамент као најпогоднија подлога за писање.

Процес прављења целулозног папира је развијен у Кини током раног 2. века, вероватно још 105. године.[1] Значајну улогу у развоју папира је имао Цај Луен дворски евнух династије Хан. Постоје и ранији археолошки фрагменти папира који датирају из 2. века п. н. е. у Кини.[2]

Почеци

Хартију је измислио Кај Лун, дворјанин кинеског цара Ву Дија. Производили су га од бамбуса, лубја и крпа размочених у води. Они су током 700 година држали у тајности начин производње хартије, све док муслимани за њу нису сазнали од једног од заробљених Кинеза након битке код Таласа 751.

Како тврди Са'алеби (умро 1038), борба између Зијада ибн Салиха и турских владара, ојачаних снагама њихових кинеских савезника, избила је око 752. године у близини реке Тараз на северу Месопотамије. Та Област се у традиционалној исламској литератури називала Туркестан зато што су ту претежно живели народи турског порекла. По завршетку борбе, Зијад је са собом повео и групу кинеских заробљеника, међу којима је било и оних који су добро познавали процес производње кинеског папира. Они су се касније настанили у Самарканду, где су развили занат којим су се традиционално бавили. Производња кинеског папира од тада је постала све учесталија, а занатлије које су се бавиле тим занатом биле су све славније и познатије. Иако се производња кинеског папира веома брзо ширила у другим градовима у калифату, ипак произвођачи „самаркандског папира”, као првог облика папира у исламској цивилизацији, засвагда су очували своју славу и традицију.[3]

Потом се ово сазнање проширило и на Европу и радионице за израду папира појавиле су се свуда где је било довољно воде за производњу папира.[4] Око 800. у Багдаду се прави прва фабрика папира.[5] Производња се ширила преко Сирије и Египта на Сицилију и у Андалузију. Тако се у 13. веку папир проширио Европом и заменио скупоцјени и ретки папирус и пергамент.

У 19. веку је индустирјализација знатно редуковала трошак производње папира. Године 1844. је канадски инвеститор Чарлс Фенерти и Немац Ф. Г. Келер независно развили процесе за пулповање дрвених влакана.[6]

Рани извори влакана

Пре индустријализације папирне продукције најзаступљенији извор влакана су била рециклирана влакна из кориштеног текстила, зване крпе. Крпе су биле од конопље, лана и памука.[7] Процес за уклањањње штампарског мастила са рециклисаног папира је изумео немачки правник Јустус Клапрот 1774. године.[7] Данас се тај метод назива деинковањем. Тек након увођења дрвене пулпе 1843. године је продукција папира постала независна од рециклираног материјала из отпадног текстила.[7]

Етимологија

Реч „папир“ је етимолошки изведена из латинске речи papyrus, која потиче од грчке πάπυρος (papuros), назива за Cyperus papyrus биљку.[8][9] Папирус густ, папиру сличан материјал који се производи из сржи биљке Cyperus papyrus, која је кориштена у античком Египту и другим Медитеранским културама за писање пре увођења папира на Блиском истоку и у Европи.[10] Мада је реч папир етимолошки изведена из папируса, ова два материјала се веома различито производе и развој првог је независтан од развоја другог. Папирус је ламинација природних биљних влакана, док се папир производи од влакана чија су својства промењена натапањем.[2]

Производња папира

Као сировину, Кинези су користили кору дуда или бамбус, Европљани су користили старе крпе од памука и лана, док се данас дрвета тачније од целулозе. Папир је изразито значајно допринео просвети и науци. Проналазак папира сматра се једним од показатеља почетка новог века. Користи се у разне сврхе и може се наћи у разним облицима.

Основно средство за ручну производњу хартије је калуп за захватање натопљене пулпе. Добри калупи са истока су лепо израђени и имали су оквир са шаркама за држање сита. Мајстор наизменично спушта и извлачи калуп из базена и лагано га тресе да би се пулпа раширила по ситу. Стезаљке се затим отворе а сито се извади. Калупи на Западу имају сито од танке жице уместо бамбуса.

Мајстор ставља калуп у базен, пулпа се скупља на калупу а течност се цеди остављајући на ситу беома танак слој влакана. Цеђење се ради када влакна направе влажан лист папира. Листови се слажу један преко другог, а вода се циједи притиском камена или помоћу пресе која личи на штампарску. Исламски мајстори први су направили хартију у боји. Они су на њу наносили чак и златне или сребрне зачкице. Данас имамо хартију у свим могућим бојама. Нарочита хартија као она што су је правили муслимани може се користити за писање диплома или свједочанстава.

Хемијско пулповање

Да би се формирала пулпа од дрвета, a chemical pulping process separates lignin from cellulose fibres. This is accomplished by dissolving lignin in a cooking liquor, so that it may be washed from the cellulose; this preserves the length of the cellulose fibres. Paper made from chemical pulps are also known as wood-free papers–not to be confused with tree-free paper; this is because they do not contain lignin, which deteriorates over time. The pulp can also be bleached to produce white paper, but this consumes 5% of the fibres; chemical pulping processes are not used to make paper made from cotton, which is already 90% cellulose.

There are three main chemical pulping processes: the sulfite process dates back to the 1840s and it was the dominant method extent before the second world war. The kraft process, invented in the 1870s and first used in the 1890s, is now the most commonly practiced strategy, one of its advantages is the chemical reaction with lignin, that produces heat, which can be used to run a generator. Most pulping operations using the kraft process are net contributors to the electricity grid or use the electricity to run an adjacent paper mill. Another advantage is that this process recovers and reuses all inorganic chemical reagents. Soda pulping is another specialty process used to pulp straws, bagasse and hardwoods with high silicate content.

Механичко пулповање

There are two major mechanical pulps: thermomechanical pulp (TMP) and groundwood pulp (GW). In the TMP process, wood is chipped and then fed into steam heated refiners, where the chips are squeezed and converted to fibres between two steel discs. In the groundwood process, debarked logs are fed into grinders where they are pressed against rotating stones to be made into fibres. Mechanical pulping does not remove the lignin, so the yield is very high, >95%, however it causes the paper thus produced to turn yellow and become brittle over time. Mechanical pulps have rather short fibres, thus producing weak paper. Although large amounts of electrical energy are required to produce mechanical pulp, it costs less than the chemical kind.

Деинкована пулпа

Paper recycling processes can use either chemically or mechanically produced pulp; by mixing it with water and applying mechanical action the hydrogen bonds in the paper can be broken and fibres separated again. Most recycled paper contains a proportion of virgin fibre for the sake of quality; generally speaking, de-inked pulp is of the same quality or lower than the collected paper it was made from.

There are three main classifications of recycled fibre:.

- Mill broke or internal mill waste – This incorporates any substandard or grade-change paper made within the paper mill itself, which then goes back into the manufacturing system to be re-pulped back into paper. Such out-of-specification paper is not sold and is therefore often not classified as genuine reclaimed recycled fibre, however most paper mills have been reusing their own waste fibre for many years, long before recycling became popular.

- Preconsumer waste – This is offcut and processing waste, such as guillotine trims and envelope blank waste; it is generated outside the paper mill and could potentially go to landfill, and is a genuine recycled fibre source; it includes de-inked preconsumer (recycled material that has been printed but did not reach its intended end use, such as waste from printers and unsold publications).[11]

- Postconsumer waste – This is fibre from paper that has been used for its intended end use and includes office waste, magazine papers and newsprint. As the vast majority of this material has been printed – either digitally or by more conventional means such as lithography or rotogravure – it will either be recycled as printed paper or go through a de-inking process first.

Recycled papers can be made from 100% recycled materials or blended with virgin pulp, although they are (generally) not as strong nor as bright as papers made from the latter.

Адитиви

Besides the fibres, pulps may contain fillers such as chalk or china clay,[12] which improve its characteristics for printing or writing.[13] Additives for sizing purposes may be mixed with it or applied to the paper web later in the manufacturing process; the purpose of such sizing is to establish the correct level of surface absorbency to suit ink or paint.

Формирање папира

The pulp is fed to a paper machine where it is formed as a paper web and the water is removed from it by pressing and drying.

Pressing the sheet removes the water by force; once the water is forced from the sheet, a special kind of felt, which is not to be confused with the traditional one, is used to collect the water; whereas when making paper by hand, a blotter sheet is used instead.

Drying involves using air or heat to remove water from the paper sheets. In the earliest days of paper making, this was done by hanging the sheets like laundry; in more modern times, various forms of heated drying mechanisms are used. On the paper machine, the most common is the steam-heated can dryer. These can reach temperatures above 200 °F (93 °C) and are used in long sequences of more than forty cans where the heat produced by these can easily dry the paper to less than six percent moisture.

Дорада

The paper may then undergo sizing to alter its physical properties for use in various applications.

Paper at this point is uncoated. Coated paper has a thin layer of material such as calcium carbonate or china clay applied to one or both sides in order to create a surface more suitable for high-resolution halftone screens. (Uncoated papers are rarely suitable for screens above 150 lpi.) Coated or uncoated papers may have their surfaces polished by calendering. Coated papers are divided into matte, semi-matte or silk, and gloss. Gloss papers give the highest optical density in the printed image.

The paper is then fed onto reels if it is to be used on web printing presses, or cut into sheets for other printing processes or other purposes. The fibres in the paper basically run in the machine direction. Sheets are usually cut "long-grain", i.e. with the grain parallel to the longer dimension of the sheet. Continuous form paper (or continuous stationery) is cut to width with holes punched at the edges, and folded into stacks.

Финоћа папира

All paper produced by paper machines as the Fourdrinier Machine are wove paper, i.e. the wire mesh that transports the web leaves a pattern that has the same density along the paper grain and across the grain. Textured finishes, watermarks and wire patterns imitating hand-made laid paper can be created by the use of appropriate rollers in the later stages of the machine.

Wove paper does not exhibit "laidlines", which are small regular lines left behind on paper when it was handmade in a mould made from rows of metal wires or bamboo. Laidlines are very close together. They run perpendicular to the "chainlines", which are further apart. Handmade paper similarly exhibits "deckle edges", or rough and feathery borders.[14]

Примене

Paper can be produced with a wide variety of properties, depending on its intended use.

- For representing value: paper money, bank note, cheque, security (see security paper), voucher and ticket

- For storing information: book, notebook, graph paper, magazine, newspaper, art, zine, letter

- For personal use: diary, note to remind oneself, etc.; for temporary personal use: scratch paper

- For communication: between individuals and/or groups of people.

- For packaging: corrugated box, paper bag, envelope, Packing & Wrapping Paper, Paper string, Charta emporetica and wallpaper

- For cleaning: toilet paper, handkerchiefs, paper towels, facial tissue and cat litter

- For construction: papier-mâché, origami, paper planes, quilling, paper honeycomb, used as a core material in composite materials, paper engineering, construction paper and paper clothing

- For other uses: emery paper, sandpaper, blotting paper, litmus paper, universal indicator paper, paper chromatography, electrical insulation paper (see also dielectric and permittivity) and filter paper

It is estimated that paper-based storage solutions captured 0.33% of the total in 1986 and only 0.007% in 2007, even though in absolute terms, the world's capacity to store information on paper increased from 8.7 to 19.4 petabytes.[15] It is estimated that in 1986 paper-based postal letters represented less than 0.05% of the world's telecommunication capacity, with sharply decreasing tendency after the massive introduction of digital technologies.[15]

Типови, дебљина и тежина

The thickness of paper is often measured by caliper, which is typically given in thousandths of an inch in the United States and in micrometers (µm) in the rest of the world.[16] Paper may be between 007 and 018 mm (0,28 and 0,71 in) thick.[17]

Paper is often characterized by weight. In the United States, the weight assigned to a paper is the weight of a ream, 500 sheets, of varying "basic sizes", before the paper is cut into the size it is sold to end customers. For example, a ream of 20 lb, 85 in × 11 in (2.159 mm × 279 mm) paper weighs 5 pounds, because it has been cut from a larger sheet into four pieces.[18] In the United States, printing paper is generally 20 lb, 24 lb, or 32 lb at most. Cover stock is generally 68 lb, and 110 lb or more is considered card stock.

In Europe, and other regions using the ISO 216 paper sizing system, the weight is expressed in grammes per square metre (g/m2 or usually just g) of the paper. Printing paper is generally between 60 g and 120 g. Anything heavier than 160 g is considered card. The weight of a ream therefore depends on the dimensions of the paper and its thickness.

Most commercial paper sold in North America is cut to standard paper sizes based on customary units and is defined by the length and width of a sheet of paper.

The ISO 216 system used in most other countries is based on the surface area of a sheet of paper, not on a sheet's width and length. It was first adopted in Germany in 1922 and generally spread as nations adopted the metric system. The largest standard size paper is A0 (A zero), measuring one square meter (approx. 1189 × 841 mm). A1 is half the size of a sheet of A0 (i.e., 594 mm × 841 mm), such that two sheets of A1 placed side by side are equal to one sheet of A0. A2 is half the size of a sheet of A1, and so forth. Common sizes used in the office and the home are A4 and A3 (A3 is the size of two A4 sheets).

The density of paper ranges from 250 kg/m3 (16 lb/cu ft) for tissue paper to 1.500 kg/m3 (94 lb/cu ft) for some speciality paper. Printing paper is about 800 kg/m3 (50 lb/cu ft).[19]

Paper may be classified into seven categories:[20]

- Printing papers of wide variety.

- Wrapping papers for the protection of goods and merchandise. This includes wax and kraft papers.

- Writing paper suitable for stationery requirements. This includes ledger, bank, and bond paper.

- Blotting papers containing little or no size.

- Drawing papers usually with rough surfaces used by artists and designers, including cartridge paper.

- Handmade papers including most decorative papers, Ingres papers, Japanese paper and tissues, all characterized by lack of grain direction.

- Specialty papers including cigarette paper, toilet tissue, and other industrial papers.

Извори

- ^ Hogben, Lancelot. "Printing, Paper and Playing Cards". Bennett, Paul A. (ed.) Books and Printing: A Treasury for Typophiles. New York: The World Publishing Company, (1951). стр. 15–31. стр. 17. & Mann, George. Print: A Manual for Librarians and Students Describing in Detail the History, Methods, and Applications of Printing and Paper Making. London: Grafton & Co., (1952). стр. 77

- ^ а б Tsien 1985, стр. 38

- ^ Велајати, Али Акбар (2016), Историја културе и цивилизације ислама и Ирана, превео Муамер Халиловић, Београд, Центар за религијске науке „Ком”. стр. 111—112.

- ^ Burns 1996, стр. 417f.

- ^ Murray, Stuart A. P. The Library: An illustrated History. Skyhorse Publishing, (2009). стр. 57.

- ^ Burger, Peter (2007). Charles Fenerty and his paper invention. Toronto: Peter Burger. стр. 25—30. ISBN 9780978331818. OCLC 173248586.

- ^ а б в Göttsching, Lothar; Gullichsen, Johan; Pakarinen, Heikki; Paulapuro, Hannu; Yhdistys, Suomen Paperi-Insinöörien; Technical Association of the Pulp and Paper Industry (2000). Recycling fiber and deinking. Finland: Fapet Oy. стр. 12—14. OCLC 247670296. ISBN 952-5216-07-1.

- ^ πάπυρος, Henry George Liddell, Robert Scott, A Greek-English Lexicon, on Perseus

- ^ papyrus, on Oxford Dictionaries

- ^ „papyrus”. Dictionary.com Unabridged. Random House. Приступљено 20. 11. 2008.

- ^ Natural Resource Defense Council

- ^ Appropriate Technology (на језику: енглески). Intermediate Technology Publications. 1996.

- ^ Thorn, Ian; Au, Che On (2009-07-24). Applications of Wet-End Paper Chemistry (на језику: енглески). Springer Science & Business Media. ISBN 9781402060380.

- ^ "Document Doubles" in a virtual museum exhibition at Library and Archives Canada

- ^ а б "The World’s Technological Capacity to Store, Communicate, and Compute Information", especially Supporting online material, Martin Hilbert and Priscila López (2011), Science, 332(6025), 60–65; free access to the article through here: martinhilbert.net/WorldInfoCapacity.html

- ^ „Paper Thickness Chart”. Case Paper (на језику: енглески). Приступљено 2017-05-27.

- ^ Elert, Glenn. „Thickness of a Piece of Paper”. The Physics Factbook (на језику: енглески). Приступљено 2017-05-27.

- ^ McKenzie, Bruce G. (1989). The Hammerhill guide to desktop publishing in business. Hammerhill. стр. 144. ISBN 9780961565114. OCLC 851074844.

- ^ „Density of paper and paperboard”. PaperOnWeb. Приступљено 31. 10. 2007.

- ^ Johnson, Arthur (1978). The Thames and Hudson manual of bookbinding (на језику: енглески). London: Thames and Hudson. OCLC 959020143.

Литература

- Burns, Robert I. (1996). „Paper comes to the West, 800−1400”. Ур.: Lindgren, Uta. Europäische Technik im Mittelalter. 800 bis 1400. Tradition und Innovation (4th изд.). Berlin: Gebr. Mann Verlag. стр. 413—422. ISBN 978-3-7861-1748-3.

- Tsien, Tsuen-Hsuin (1985). „Paper and Printing”. Joseph Needham, Science and Civilisation in China, Chemistry and Chemical Technology. Vol. 5 part 1. Cambridge University Press.

- „Document Doubles, Detecting the Truth: Fakes, Forgeries and Trickery”. Library and Archives Canada.

- Velajati, Ali Akbar (2016), Istorija kulture i civilizacije islama i Irana, preveo Muamer Halilović, Beograd, Centar za religijske nauke „Kom”. стр. 87—118.